The AKF10 series high-speed cutter is designed for batch production. It adopts a new control system and linear-guide transmission, offering high speed, high accuracy and excellent mechanical stability. The machine greatly improves overall efficiency and is highly expandable for future add-ons. It cuts fabrics, carpets, mats, rubber and more, serving industries such as apparel, automotive interiors, composite materials, gaskets, sports goods and upholstery. Depending on material and application, it is also called low-ply cutting table, single-ply cutter, automotive seat & floor-mat cutter, gasket cutter, composite cutter, automotive interior cutter, upholstery cutter, leather cutter, or luggage & footwear cutting machine.

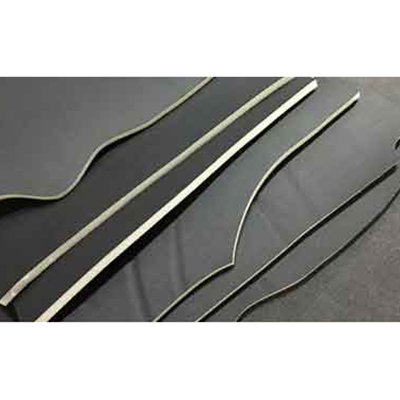

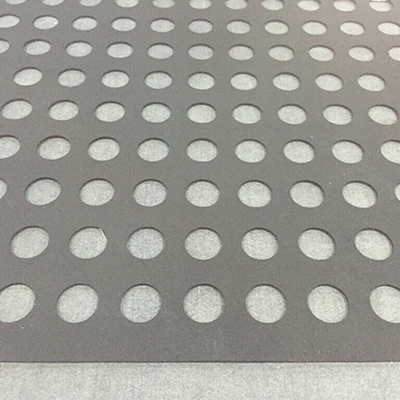

Loop pile, sponge composites, XPE, EVA, fiber blankets, faux leather, genuine leather, fabrics, plush toys, shoe linings, prepregs, glass fiber, carbon fiber, rubber gaskets, graphite seals, etc.

Automotive interiors, composite materials, sealing gaskets, sports goods, upholstery, apparel & bags, footwear & leather goods.

Model |

AKF102516 |

AKF101713 |

AKF101310 |

Effective Cutting Area |

2500 × 1600 mm |

1700 × 1300 mm |

1300 × 1000 mm |

Configuration |

Oscillating knife, pen, drag knife, foam knife, etc. |

||

Maximum Speed |

1800 mm/s |

||

Minimum Cutting Circle Radius |

1 mm |

||

Accuracy |

≤0.1 mm |

||

Maximum Cutting Thickness |

60 mm |

||

Driver |

Servo |

||

Voltage |

220 V ±10 % 50 Hz |

||

Vacuum Pump Power |

5.5 kW / 7.5 kW |

||

Data Format |

HPGL, DXF, PDF |

||

Data Interface |

Parallel, serial, USB |

||

Options |

AOKE CCD vision positioning system |

||

Footprint (L × W × H) |

3300 × 2460 × 1180 mm |

2500 × 2160 × 1180 mm |

2100 × 1860 × 1180 mm |

Remarks |

Other sizes available on request |

||

Pattern

Pattern Leather

Leather Fabric

Fabric Plain Fabric

Plain Fabric Imitation Leather

Imitation Leather Gasket

Gasket