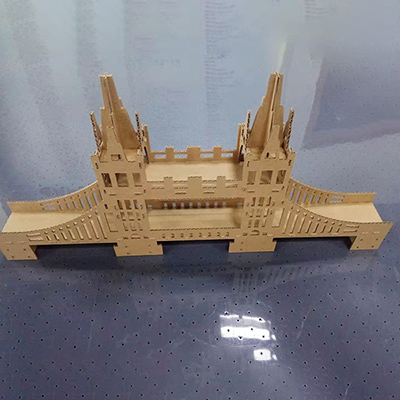

The high-speed double greyboard box cutting & prototyping machine – new DCZ70 series – is the latest generation carton & color-box prototyping system developed by AOKE. Compared with earlier models, performance has improved dramatically: faster machining speed, higher accuracy, and easier operation, all wrapped in a more futuristic look. Integrating prototyping and plotting functions in one unit, the DCZ70 series inherits AOKE’s hallmark traits of stability, speed and precision. Ideal for prototyping and short-run production at packaging companies, corrugated carton plants, color-box factories, printing houses, die-cutting shops, and rigid-box plants, it cuts corrugated board, honeycomb board, hardboard, cardboard, foam board, KT board, PVC foam board, plastic sheet, hollow board, leather, fabric and more. It has earned wide acclaim among customers in packaging, advertising, printing, die-cutting, electronics, gaskets, signage, footwear and leather goods.

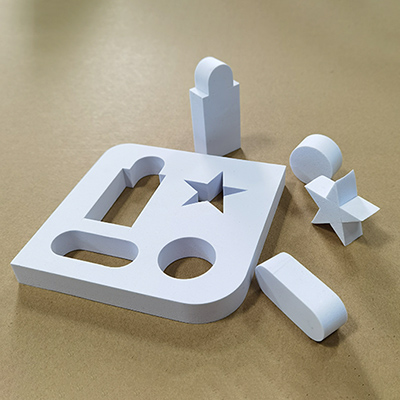

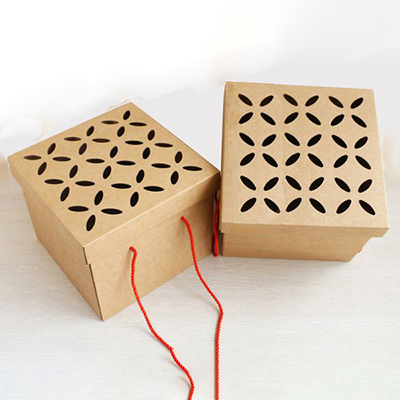

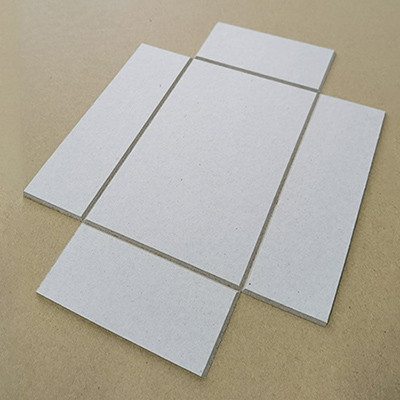

Corrugated board, honeycomb board, EPE foam, cardboard, foam board, greyboard, KT board, PVC foam board, plastic sheet, hollow board, leather, EVA, fabric loop pile, etc.

Main Application IndustriesPrototyping, cutting and short-run production for advertising, display, packaging and color-printing sectors.

| Model | New DCZ701310 | New DCZ701713 | New DCZ702516 |

| Effective Cutting Area (mm) | 1300 × 1000 mm | 1700 × 1300 mm | 2500 × 1600 mm |

| Configuration | Oscillating knife, kiss-cut knife, drag knife, V-groove knife, creasing wheel, pen, laser pointer | ||

| Maximum Speed | 1400 mm/s | ||

| Minimum Circle Diameter | 2 mm | ||

| Maximum Cutting Thickness | 30 mm | ||

| Driver | Servo | ||

| Cutting Accuracy | ±0.1 mm | ||

| Repeat Accuracy | ≤0.1 mm | ||

| Functions | Oscillating cutting, creasing, dashed-line cutting, kiss-cutting, V-groove cutting, die-board drawing, laser positioning, infrared safety | ||

| Cutting Media | Up to 30 mm EPE/EVA, 15 mm corrugated board, 3 mm greyboard/cardboard, 1.5 mm PVC sheet, etc. | ||

| Equipment Composition | Worktable, control cabinet, vacuum pump, air compressor | ||

| Media Fixing Method | Vacuum suction. When cutting breathable materials such as fabric-covered boxes, cover the material with a film. | ||

| Vacuum Pump | 5.5 kW, 380 V | ||

| Data Format | HPGL, DXF, PDF | ||

| Voltage | 220 V ±10 %, 50 Hz | ||

| Data Interface | Parallel, serial, USB | ||

| Options | AOKE CCD vision positioning system, V-groove knife, foam knife | ||

| Footprint (L × W × H) | 2200 × 1860 × 1180 mm | 2600 × 2160 × 1180 mm | 3400 × 2460 × 1180 mm |

| Remarks | Other sizes available on request | ||